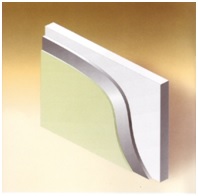

Wall Panel

100X56 structural I-beams are used to form High Loadbearing framework for the prefabricated composite Operating Theatre’s external structure. The wall panels and the arching ceiling panels are fabricated to meet actual site situation from 1.5mm first-class electrolyzed steel plate. Beneath every wall panel, a lining board is appended in order to enhance its ability against collision with thermal and sound insulation. All wall panels and appended elements are factory prefabricated and delivered to the site directly for installation without delay. Precise technology as well as excellent workmanship guarantees the product quality.

The loadbearing in structure forming the exterior of the theatre is firmly bolted to the building to achieve total stability. As such, every wall plate is sturdily supported, making it possible to append additional devices afterwards. Plates and integral structures are bolted together. The rigidity of the interior casing is therefore greatly enhanced. The effect achieved through the technology of bolted joints is more reliable and durable than spot welded joints. Metal stuffing is filled to the junctions. Smooth, seamless and airtight effect is accomplished by meticulous polishing work that follows. All corners in the Operating Theatre are

designed for easily cleaning and sterilizing.