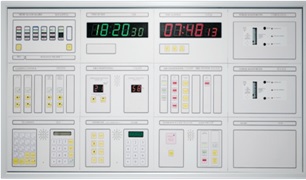

Control Panel

We apply advanced control system to the clean air system by a set of interlocking program control, in which cooling pipe and electricity-heating humidifier will not operate at the same time for the sake of energy saving. Thanks to the control valve, the room temperature remains stable. This cost-cutting sophisticated control technology not only ensures an absolute clean environment for operation, it also saves energy to the greatest extends. At present, some companies use ordinary air-conditioning control modules, causing unstable room temperature, which is extremely uncomfortable for doctors and nurses, it wastes energy and operating costs. Some companies offer only on and off switch control. When such system is not in operation, the air-conditioning will be shut off completely and the room air will be stagnant. This will cause the pressure difference disappear gradually and thus cross infection will be inevitable. It will take at least ten minutes to replace the contaminated air before the Operating Theatre can be put in use again. The worse is that the operation may be carried out while the purging procedure is still in progress. Our air-conditioning control system uses a built-in inverter to maintain the air handing unit running low speed when the O.T. room is not in use and the control panel is switched off. The Operating Theatre can then be maintained at minimum ventilation, enabling the room air at constant flow and positive pressure. This design prevents cross infection and putting the Operating Theatre always ready for use to meet the need for emergency operation. The air cleaning system is controlled by duplex controlling systems.